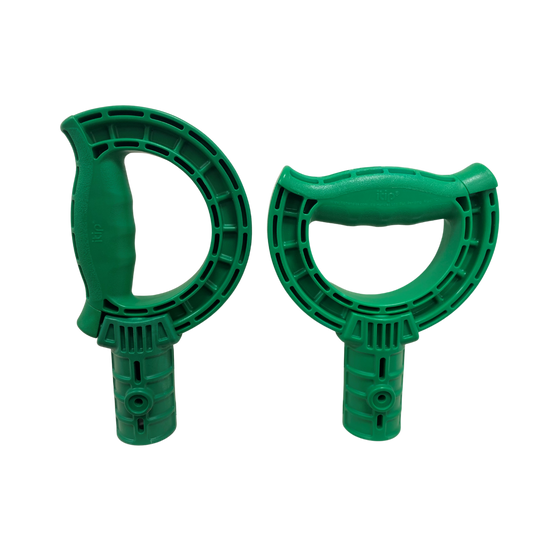

Safety Handles protecting loved ones

In the realm of home wheelchairs, where comfort is paramount, iRoll Safety Handles mark a transformative advancement. While wheelchair designs have evolved, the area ripe for improvement lies in enhancing the experience for family members, friends and loved ones pushing the wheelchair. Safety Handles offer a superior grip that dynamically adjusts to the attendant's height, effectively reducing strain on the wrist (CTS*) and eliminating the need to arch the back. Particularly on inclines and drops, Safety Handles truly shine, providing heightened grip, control, and stability.

With the added bonus of being available in a range of colours, Safety Handles not only elevate the ergonomic aspects of wheelchair assistance but also add a touch of personalisation to the caregiving experience. Note if you have a handle break system, please check the fit by contacting Safety Handles.

Tested by the Health & Safety Executive

One often overlooked aspect is the safety of caregivers, a critical consideration that Safety Handles address with precision. These handles have undergone comprehensive analysis by the Health and Safety Executive (HSE), attesting to their efficacy in mitigating the causes of musculoskeletal disorders. Caregivers who repetitively push wheelchairs at incorrect heights are susceptible to severe, long-term injuries. Safety Handles emerge as a solution, providing not only ergonomic support but also a tangible commitment to safeguarding the well-being of those who selflessly care for others. The HSE reinforce the value of Safety Handles in promoting a safer and more sustainable caregiving environment. Note for 'pram style' handles you will need ezTip rather than iTip Safety Handles.

iTip Safety Handles for wheelchairs

-

iTip Safety Handles (Domestic & Home) (Price inc VAT)

Regular price £25.00Regular price

-

-

HSE Summary

Click for HSE Summary reportEvaluation of iTip Safety Handles by the Health and Safety Executive of the UK Government